| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

SCHTEC MAK SAN VE TİC AŞ

İkitelli OSB Süleyman Demirel Bulvarı Heskop İş Modern Sanayi Sitesi J Blok No: 44 34490 / Başakşehir / İSTANBUL / TÜRKİYE

|

Contact Info: +90 212 852 0161

|

Hall: 3

Stand: 317

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Deneyimli Kadrosu ve Tecrübeli ekibi ile 02.08.2013 tarihinde kurulan Schtec Makine San. Ve Tic. A.Ş. , 500 m² ile başladığı üretim alanını yeni yatırımları ile birlikte toplamda 9.000 m² ye çıkartarak PVC ve Alüminyum Kapı Pencere sektörüne yeni bir bakış açısı ile hizmet vermeye devam etmektedir. Schtec, yılların birikimine ve deneyimine sahip PVC İşleme Makineleri konusunda Türkiye de ilkleri gerçekleştirerek değerli müşterilerimizin hizmetine sunmuş, sektörün teknik olarak önemli bilgi birikimine sahip, satış konusunda tecrübeli bir kadronun faaliyetlerine devam edebilmesi ve bu tecrübenin oluşturduğu yeniliklerden ve yüksek teknolojiye sahip makinelerden müşterilerimizin de yararlanabilmesini düşüncesiyle kurulmuştur. Bugün Türkiye nin sektöründe en hızlı yükseliş yapan 1. firması olarak yoluna devam etmektedir.

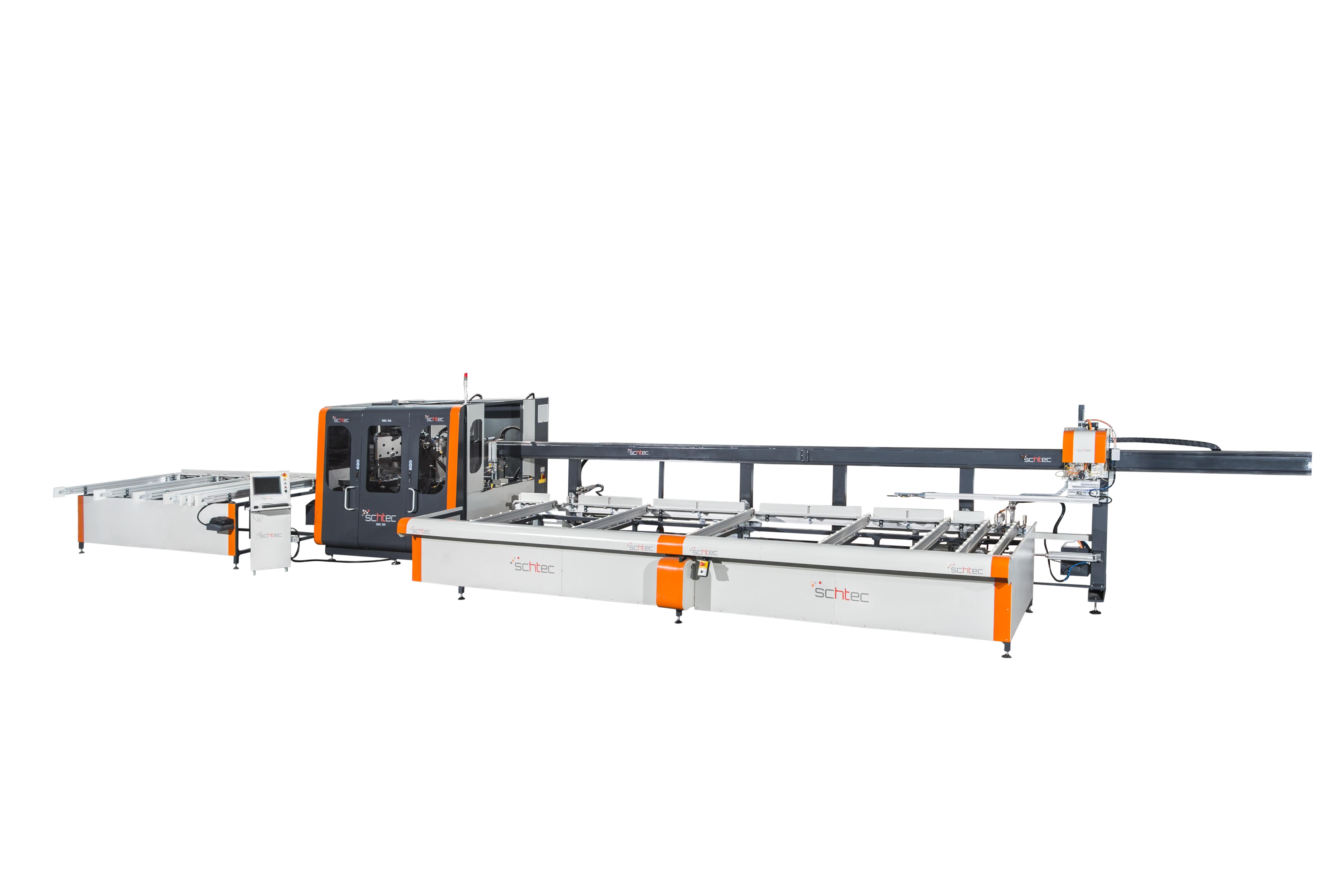

SMC 360 Model Description: This 2 separately controlled CNC processing unit can do all operations with 14 tools on PVC profiles such as cutting, marking, opening key holes, copy routing for water slot milling, hinge holes, handle holes etc. It comes with a 500mm saw blade, and pvc profiles can be cut between 30 150 degrees with 0.1 degree accuracy Servo controlled and capable of automatic positioning according to profile height axis on saw blade by way of this advance fast and rigid cutting. Saves time by simultaneously opening multiple holes on door profiles, such as door handles, slots by the axis control system on 2 separately router unit. With the processed profile, 11 pieces can be loaded on the machine. (Max.length 6.5 m) Precision magnetic encoders used to minimize user errors minimize profile width and height are checked and processed New design of loading station allow profiles to be loaded simultaneously. This feature saves time from loading process. Private HMI software developed by Schtec Software Departmant allows different kinds of window design program data files to be uploaded on machine. Simultaneous optimization on the machine allows the machine to optimize itself on the waste profiles All alarms and machine faultsare displayed on HMI along with solutions 15 Touch Screen and high performance industrial PC with Windows XP Embeded system. This system can operate fanless between 0°C and 55°C. Industrial PC Based Servo Control System (Beckhoff) Online diagnostic and troubleshooting via user friendly interface. File transfer by USB or ethernet network and remote desktop connection by WiFi or Ethernet connection Central lubrication system reduces the time spent on maintanence Automatic dust collection system sucks out all pvc dusts and removes wastes fast with 2 different carriers Optional ; Optional screwing station having two screw units allows simultaneous screwing of reinforcement steel via servo controlled axes system For operations which can be done on profiles with a height greater than 120 mm and maximum cutting height, please inquire to us SMC 360 Model Technical Features: Voltage : 400 V, 3 PH, 50-60Hz Power Consumption : 14 kW, 35 A Max. Profile Height : 120 mm ( up to 170 mm only cutting process) Min. Profile Height : 40 mm Max. Profile Width : 130 mm Min. Profile Width : 35 mm Max. Profile Bar Length : 6.500 mm Max. Process Length for Profile : 6.000 mm Maximum Cutting Length : 3.500 mm (can be increased when it needs) Minimum Cutting Length : 370 mm Min. Process Length for Profile : 900 mm Tool Diameter : 5 mm / 6 mm Carbide Fast Tool Tool rpm : 18.000 rpm Max. Axes Speed (Processing) : 50 m./min. Max. Axes Speed (Saw) : 100 °/sec. Max. Axes Speed (Carrier) : 40 m./min. Air Pressure : 6-8 Bar

Standard Features SSL 1 Four Head Welding and CNC Corner Cleaning Automation Line An integrated system which consists of a WM 740 four point welding machine, a CS 810 cooling and buffer station, a TS 820 Robotics design turning station and a CM 620 CNC Corner Cleaner All process is controlled by industrial PC systems from welding to cooling,to turning and finally to cleaning WM 740 Four Head Welding Machine Welds four corners of PVC profiles simultaneously at 90 °with high sensitivity and strength Beckhoff brand, high performance industrial PC operated by Windows XP Embedded. Fanless motherboard system works between 0°C 55°C, and it comes with a 15 touch screen display Data transfer via ethernet network connection, wireless network connection or USB interface Welding parameters are defined by the user for every individual profile(up to 10,000 profiles) Welding temperature, melting and welding times can be adjusted individually for each profile type. All machine axes are moved by hardened steel ball screw which provides accuracy and durability. PC controlled (PID) heat control system to obtain strong welding results in compliance with standards. Summer / winter working mode is automatically selected,so the temperature adjustment is done easily Horizontally placed strong mechanical heating plates distribute heat homogeneously without being affected from difficult working conditions. Easy and fast change for teflons by specially designed roll up teflon system. Easy and fast change for welding moulds Works effectively by compressed air supplied to the system White or colour profiles can be weld with the same sensitivity Central lubrication system minimizes maintenance time Reports can be created for daily, weekly, monthly and annual production Light barriers and safety equipment confors to CE machine design with full security Stable and accurate data transfer between this machine and the CNC corner cleaning machine via Industrial quality Ethernet connection All the error messages and system status can observed on screen by HMI software program developed by the Schtec software department Service to the entire automation system,trouble shooting and fault removals can be done by remote connection TS 820 Turning Station with the Robotics Arms; High speed and high accuracy turning operation via a robotic system with strong and fast mechanical turning arms Stable turning process with highly durable turning arms Turning speed calculation is done automatically for each frame s geometric shape, reinforcement steel weight and all other factors included. All machine axis are moved by hardened steel rack and pinion gear system which provides accuracy and durability Turning robot spends the minimum energy and the least amount of time by synronochizing its actions with the CNC machine s fence system. Its compact design allows it to occupy the smallest working area possible, which is 12 m² less than its competitors. Turning time is 1 second for small frames and between 1,5 4 seconds for all other sizes. CS 810 Cooling and Buffer Station; Works between a corner cleaner and a welding machine. Provides cooling time for the profiles coming from the welding machine prior to sending them the corner cleaning machine. Cooling time is set through the welding machine s control panel. Helps increase the production capacity by storing the profiles coming from the welder before sending them to the corner cleaner. CM 620 CNC Corner Cleaning Machine High speed and accuracy corner cleaning with Servo System controlled 2 Axes Automatic knife selection for selected profile foil type (colour / white) High quality corner cleaning result through durable special knife and bit designs High quality cleaning results on surfaces by automatic measurement system Industrial PC Based Control System (Beckhoff) Remote desktop connection by way of Wifi or Network connection File transfer by USB or network Easy programming support via DXF,DWG file extensions Central lubrication system for all bearings, axis a

No represented companies found.

The company has no registered brand information.

TR

TR