| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

EMMEGI ALM. ÜRÜNLERİ İÇ VE DIŞ TİC LTD ŞTİ

ÇOBANÇEŞME MAH. SANAYİ CAD. NO: 44 NİSHİSTANBUL D BLOK D: 94 / BAHÇELİEVLER / İSTANBUL / TÜRKİYE

|

Contact Info: +90 544 485 2440

|

Hall: 3

Stand: 303 B

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Emmegi represents a system that integrates the solution, knowledge and technology offered to the customer. Emmegi s story began in 1970 in Limidi di Soliera (Modena, Italy), where the company still has its headquarters. Founded by Giuseppe Caiumi, the company has maintained its position as an international leader in the design, manufacture and marketing of aluminum, light alloy, PVC and steel profile systems for over 50 years. Continuous innovation, maximum quality, advanced logistics solutions, and high level of professionalism are our company s distinctive strengths. Today we are a well-known solution partner in process consulting.

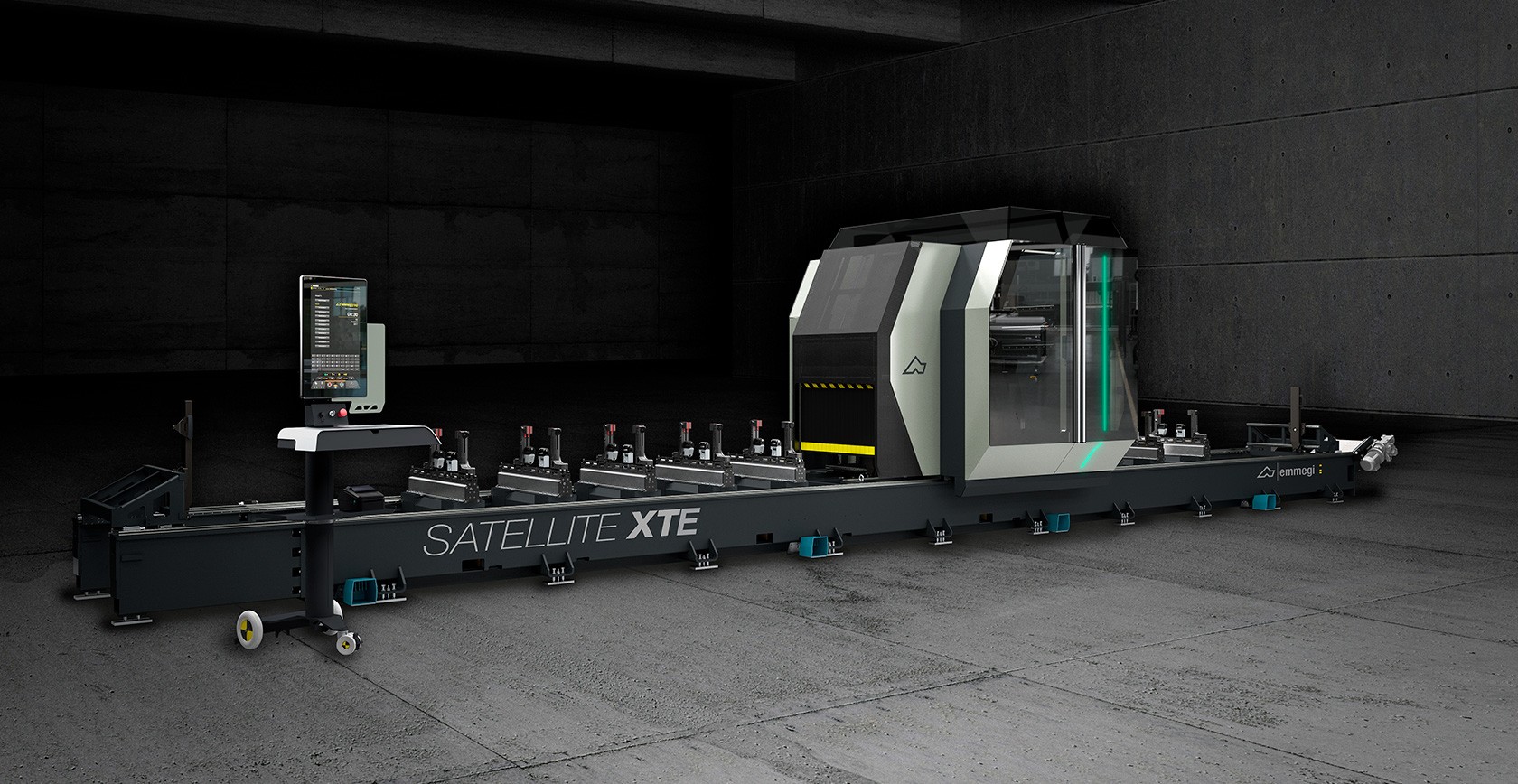

5 CNC spindles, mobile portal, generally on large size aluminum, PVC, light alloy and steel bars or parts It is a work center designed to carry out milling, drilling, tapping and cutting work. of the machine The moving part is formed by a motorized portal with a precision rack. High power HSK-63F tool connected electromandrel (15 kW in S1) allows even difficult machining to be carried out with excellent precision and speed. It allows. The 24-slot tool storage in the mobile gantry significantly shortens tool change times It is equipped with a lever system. The 500 mm blade is placed separately in a special warehouse. pendulum of the machine It is possible to use in mode; Since part replacement (loading/unloading) can be done in masked time, this work This method allows machine downtime to be minimized. Positioning of vises from the portal This functionality can be further enhanced with the dynamic pendulum version as it can be executed completely independently. possible. In addition, it is possible to process different parts between two work areas. The crankcase of the portal, its operator In addition to protection, it also reduces the noise impact on the environment.

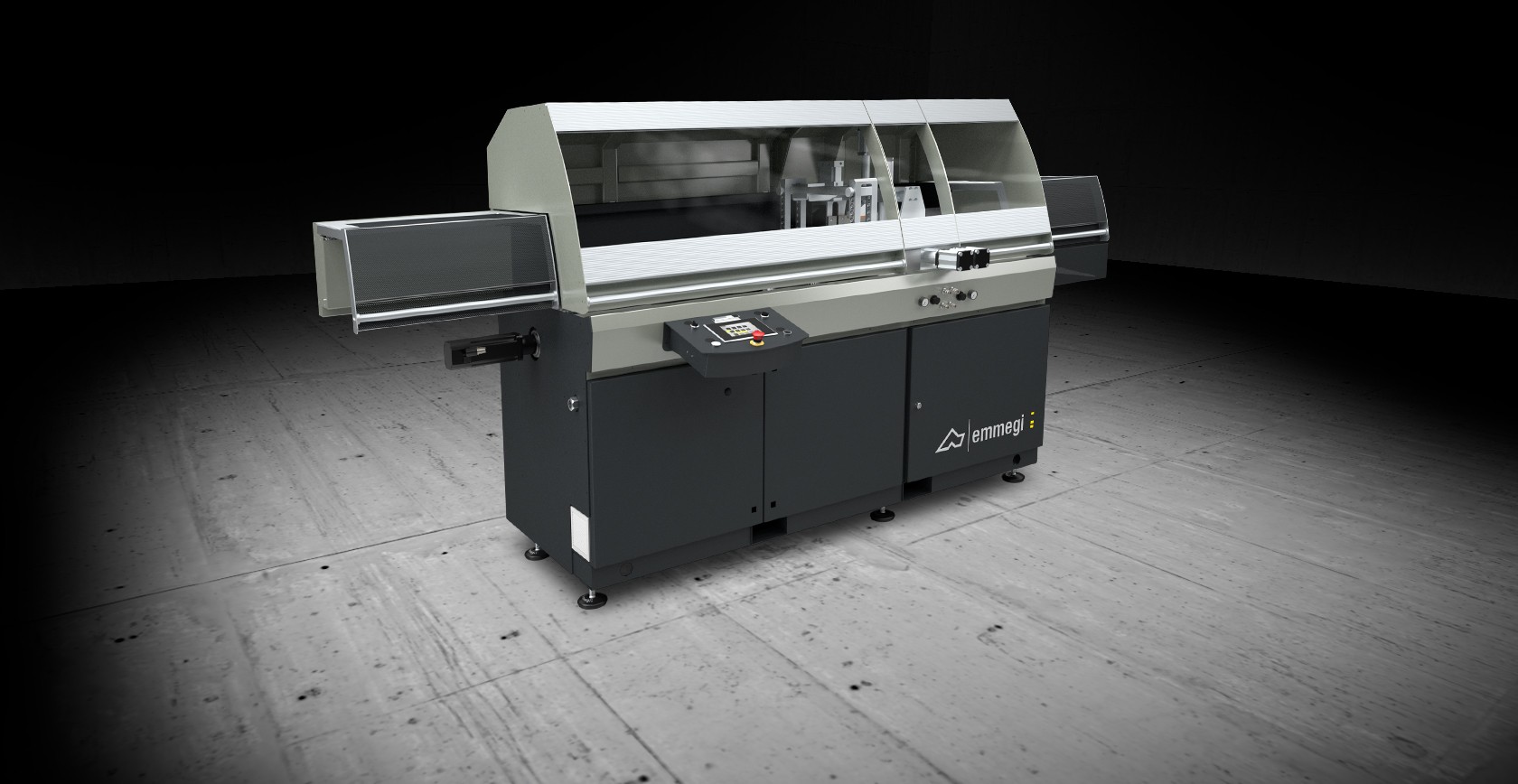

It allows the work on 3 sides of the part, the tool rotates automatically on three fixed positions, with 3 controls axis CNC working center. For machining aluminium, PVC, light alloy bars or parts in general. 9 slotted manual tool storage, one or two automatic storages with 4 slots each, mountable on either side of the cabinet can be added. The profile is positioned via a pneumatic stop on the left, fixing via the X-axis provided by 4 sturdy vices that are automatically positioned. A second pneumatic stopper is installed on the right side. Its optional installation allows for out-of-size processing of bars that are twice the length according to the working area. In addition, there is a movable system that simplifies part loading/unloading and significantly increases the workable cross section. It has a working plane.

The controlled 4-axis CNC workbench is suitable for working laths, aluminum parts, PVC, light alloys and steel parts up to 2 mm thick. Vise groups with automatic positioning. It has a 4-slot or (optionally) 8-slot tool storage that allows loading of 2 angular units and a disc mill to machine 5 faces of the part. Processes bars up to 4 m in length. The 4th axis of the CN allows the electro chuck to be rotated between 0° and 180° and to be placed at any intermediate angle. Therefore, the machine can perform processing on the upper face and side faces of the profile at every slope in the aforementioned range. Furthermore, the movable workbench facilitates the loading/unloading of the part, significantly increasing the working cross section.

Electronic double-head cutter with automatic movement of the moving head via a brushless motor controlled by numerical control. Pneumatic inclination of cutting units between 90° and 22°30 (outside) with mechanical adjustment system of intermediate angles. Oleo pneumatic blade advancement.

3-axis double-head cutter with angle management within the range of internal 15° and external 45°, controlled by automatic movement of the moving head. The advancement of the blades is realized by oleo-pneumatic cylinders. 500 mm blade. Available with 5 m or 6 m long utility cut.

Automatic cycle, rising single-head cutting machine for 90° cuts, equipped with electric bar feed system with CN. It can be configured with blades of four different diameters, the blades are electric CN progressive. For cutting needs that require perfect finishing, it can be equipped with an optional pneumatic system that provides automatic separation of the cut piece; This system prevents the traces usually left on the return of the machine on machines that perform this type of cutting. In addition, it can be equipped with an inverter to adjust the rotation speed of the blade and best adapt it to the profile to be cut. It can be equipped with an automatic bar loading tank and customized with a punching unit for specific needs.

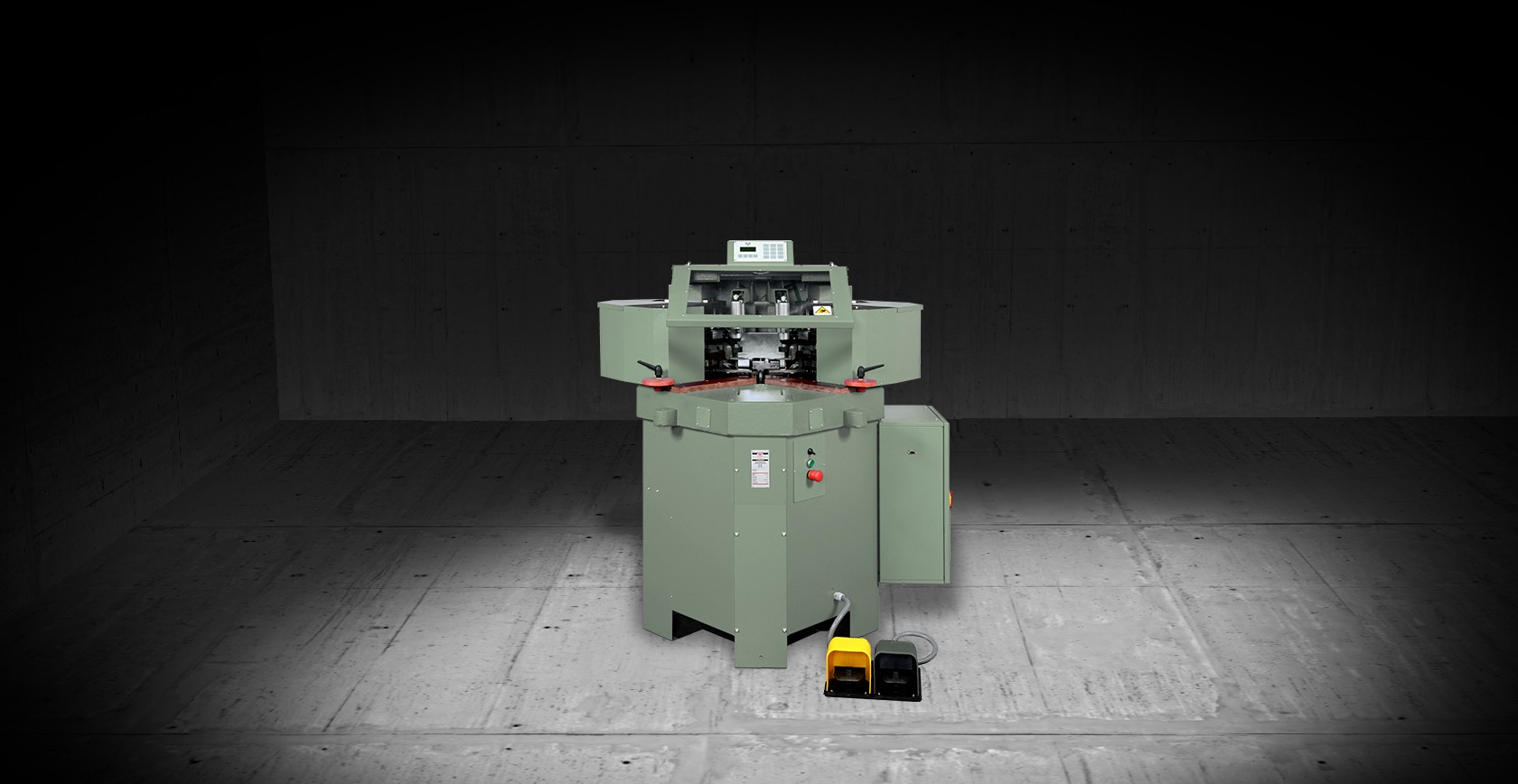

Curler for closing corners of aluminum profiles for doors, windows and facades. The machine is managed by an electronic system that can store the bending coordinates for each profile. This information is needed by the operating system for automatic positioning of the reference fork and bending tools of the profiles. Forks and tools are automatically placed when the profile to be processed is called. The blades are universal for all profiles and the system notifies the operator if a tool needs to be replaced.

- EMMEGI

TR

TR