UNİMAK MÜH. HIZ. VE MAK. SAN. TIC. LTD. STI.

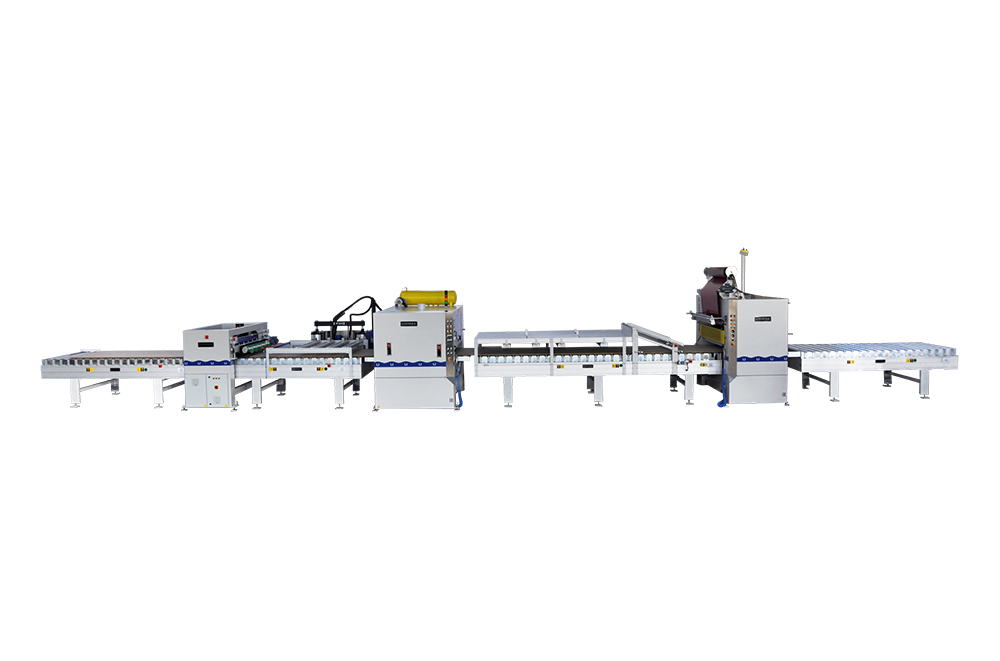

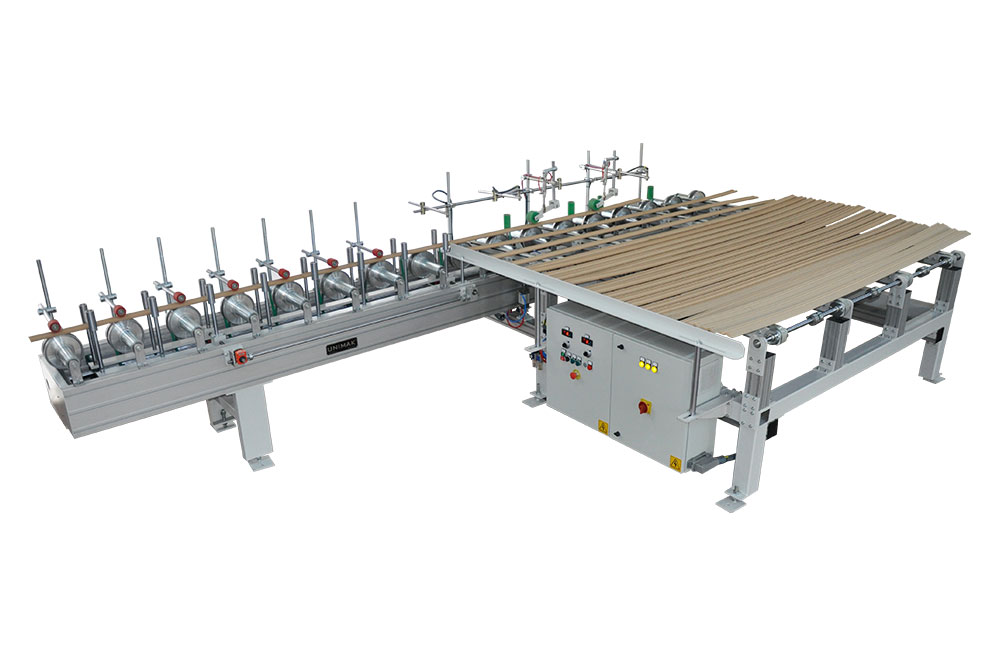

UNIMAK, with 50 years of experience on machine production and its expert staff, produces and constantly develops systems which integrates production with automation such as wide surface lamination and wrapping lines, furniture profile wrapping, frame-casing, edgeband slitting, protective tape slitting, loading-unloading systems, full automatic frame-casing and profile production lines requested by woodworking industry. For continuous customer satisfaction, starting from constant training and development philosophy, UNIMAK proceeds to increase its capacity and employee quality, with its team formed with experienced engineers and technicians. By following the developments in the wrapping and slitting technologies at the right time and earning its prestige, UNIMAK has become the most preferred brand over 90 countries in the world.